The loading conditions can be severe (pressure, speed, temperature, humidity) in case of both dynamic and static loading. The studied materials are of numerous types: metals, composite materials (organic or metallic matrix), ceramics, elastomers or polymers.

Fatigue is a recurring matter in the research conducted by the Tribology & Materials team. It is a principle that consists in the accumulation of damage under dynamic stress which can result in the destruction of a given component at its core (volume fatigue) or at its surface (surface fatigue, involved in fretting-fatigue or micro-spalling). The study of these phenomena requires modelling work, as well as experimental work using original devices developed in the laboratory.

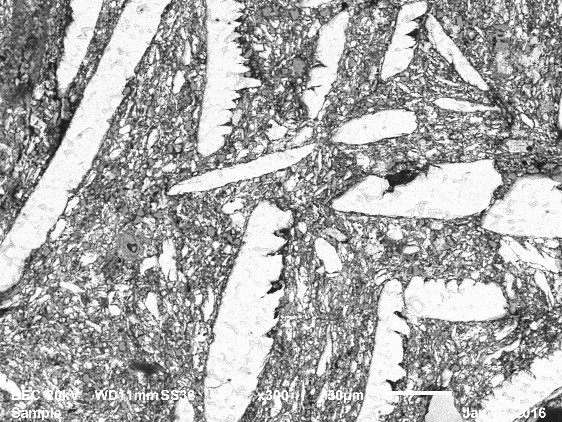

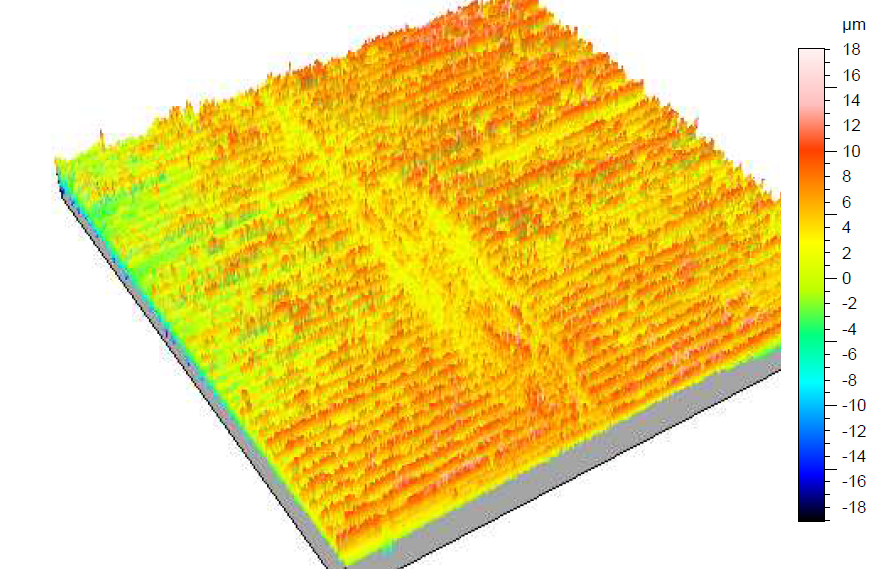

The study of micro-geometry is a means to put the materials properties at the centre of the high tribological performance of components that are in contact with each other. The research effort focuses on understanding the phenomena induced locally by the specific features of any component’s surface. One specific attribute of functional surfaces is their roughness, with altitude variations of the order of a micrometre, which by nature results in discontinued and stochastic contact between two components. Differences in nature and properties between the materials used at the surface of a component and at its core should also be taken into account, as well as differences between components in contact with each other.

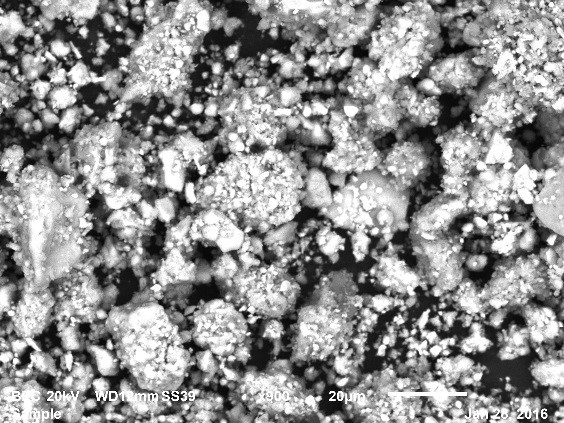

Finally, damage analysis enables to enhance these researches, in order to relate damage to the micro-structures of different scales that can be observed with a given material. Damage can be induced by several types of loadings of mechanical (tension, torsion, bending, shock, crash-test, etc.) or thermal nature (welding for example). The development of manufacturing processes primarily based on powder metallurgy will complete this project. Those processes will enable to optimise material properties and take environmental considerations into account by using residual materials (metal chips or elastomers) in the composition of subsequently created alloys.

Keywords

Tribology, , damage, fatigue, fretting, micro-geometry, mixed lubrication, materials, polymer matrix composites, metallic matrix composites, recycling.

Team members

- Akrum ABDUL-LATIF (Professor, University Institute of Technology (IUT) of Tremblay)

- Rachid BALEH (Research associate, University Institute of Technology (IUT) of Tremblay)

- Emin BAYRAKTAR (Professor at ISAE-Supméca)

- Jean-Philippe CRETE (Associate professor)

- Tony DA SILVA BOTELHO (Professor)

- Julien FORTES DA CRUZ (Associate professor)

- Geneviève INGLEBERT (Professor emeritus)

- Olga KLINKOVA (Associate professor)

- Isabelle LEMAIRE-CARON (Associate professor)

- Muriel QUILLIEN (Associate professor)

- Maria-Letizia RAFFA (Assistant Professor)

- François ROBBE-VALLOIRE (Professor), recently retired

- Imad TAWFIQ (Professor)

- Donné RAZAFINDRAMARY (Associate professor, IUT Tremblay)

- Amor BOUDEN (Associate professor, IUT Tremblay)

Doctoral candidates

Konstantinos NIKOLAKOPOULOS, Amal BECHIKH, Rémi PIEGARD, Oumeyama HAMLAOUI, Bouthania EL AOUD, Mathieu ARROUZÉ.

Head of the team

Tony Da Silva Botelho

01 49 45 29 16