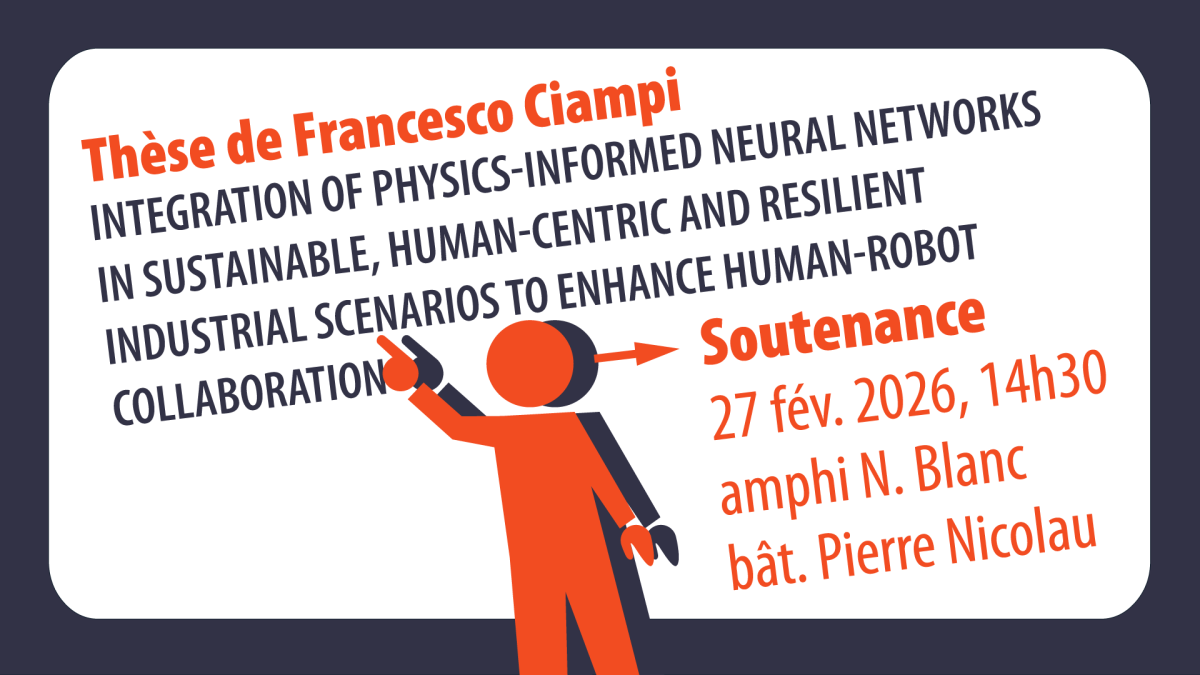

On Friday, 27 February at 2:30 p.m., Mr. Francesco Ciampi will defend his thesis entitled Integration of Physics-Informed Neural Networks in Sustainable, Human-Centric and Resilient Industrial Scenarios to Enhance Human-Robot Collaboration at ISAE-Supméca. His thesis was supervised by:

- Prof. Stanislao Patalano, UniNa (Naples),

- Dr. Thierno M. L. Diallo, ISAE-Supméca,

- Dr. Faïda Mhenni, ISAE-Supméca,

- Prof. Jean-Yves CHOLEY, ISAE-Supméca.

Doctoral comitee

- Prof. Peter HEHENBERGER, FHOÖe

- Prof. Daniele REGAZZONI, UniBg

- Prof. Vito RICOTTA, UniPa

Key words

# Industry 5.0

# Human-Robot Collaboration

# Physics-Informed Neural Networks

Abstract

The emergence of Industry 5.0 marks a paradigm shift in manufacturing, emphasizing human-centric, resilient, and sustainable systems. A central challenge within this vision is the design of effective human–robot collaboration (HRC), where robotic systems must operate safely, adaptively, and efficiently alongside human operators. Accurately modelling and predicting the dynamic interactions in such environments is critical for operational safety and productivity, yet it is often hindered by limited data availability and the complexity of coupled human–robot processes.

The dissertation investigates the application and integration of Physics-Informed Neural Networks (PINNs) to address these challenges. Unlike conventional purely data-driven machine learning methods, PINNs incorporate physical knowledge directly into the learning process, enhancing model robustness, physical consistency, and generalization. Methodologically, this work extends PINNs beyond their traditional use in differential-equation-governed problems to industrial scenarios, where physical knowledge may take the form of algebraic relations, empirical rules, or low-fidelity system models. A generalized training framework and composite loss functions are developed to exploit heterogeneous knowledge sources and to ensure physical consistency across multiple operational conditions. A systematic benchmarking procedure is established, allowing PINNs to be evaluated against standard machine learning and physics-based approaches in terms of predictive accuracy, interpretability, and robustness. The proposed methodology is validated on several industrial use cases. First, PINNs are applied to two industrial systems within the automotive sector for model validation: predicting the thermal power of an Air Handling Unit (AHU) and the temperature profile of a degreasing tank. Second, collision detection in HRC scenarios is addressed for a 6-degree-of-freedom robotic arm, demonstrating the models’ capacity to enhance safety in shared workspaces. Third, energy consumption prediction for a mobile manipulator is estimated to support the collaborative execution of reconfiguration tasks on a Cyber-Physical Production System (CPPS).

Finally, the integration of PINNs with enabling Industry 5.0 technologies is explored. Two frameworks that complement the industrial applications are discussed: one using Extended Reality (XR) interfaces to provide real-time visualization and monitoring of predictions and system data, enhancing operator situational awareness; and another embedding PINNs within a Digital Twin environment coupled with XR, enabling immersive and interactive execution of CPPS reconfiguration. This work therefore provides a comprehensive, end-to-end framework that bridges data-driven and physics-based modelling, supports human-centric decision-making, and enables adaptive, interpretable, and resilient predictive capabilities in modern industrial systems.